Professional CNC Machining Services by Xiamen Dibo Metal Technology

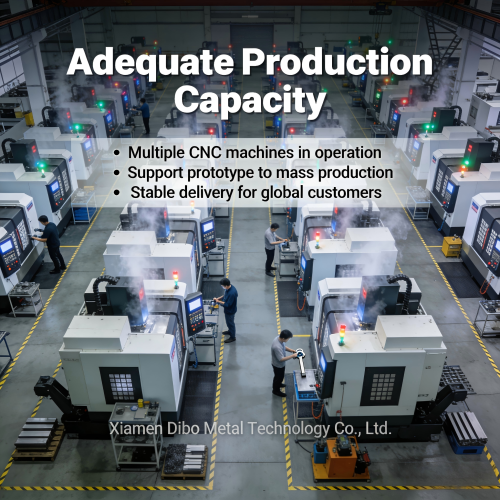

Why Choose Xiamen Dibo Metal Technology? At Xiamen Dibo Metal Technology Co., Ltd., we are a premier provider of high-precision CNC machining solutions. Based in the manufacturing hub of Xiamen, we leverage advanced technology and years of industry expertise to deliver custom metal and plastic components that meet the most rigorous international standards. Whether you need a single prototype or large-scale production, we are your reliable partner for precision and quality.

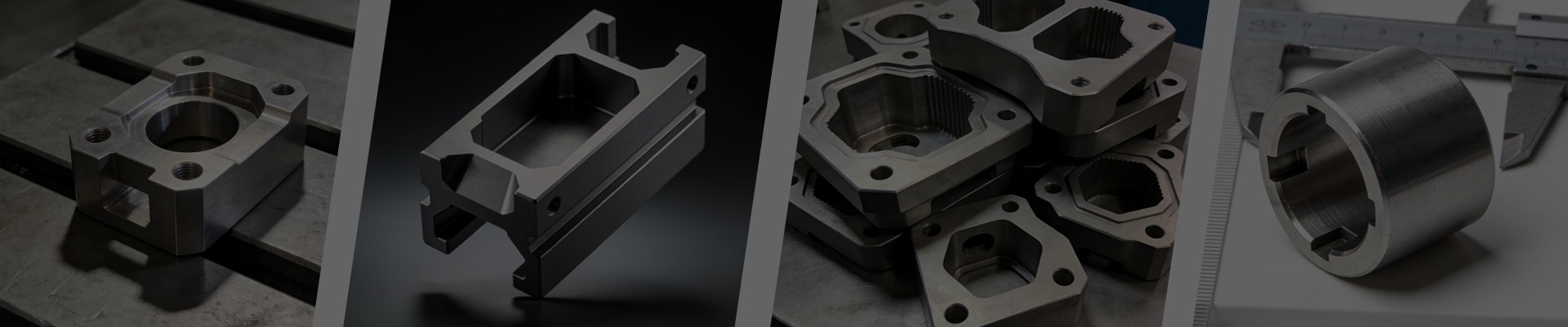

Our Core Capabilities We offer a full suite of machining services to bring your complex designs to life:

- CNC Milling (3, 4, & 5-Axis): Precision machining for complex geometries and structural components.

- CNC Turning: High-speed production of cylindrical parts with superior surface finishes.

- Integrated Manufacturing: One-stop service combining milling, turning, drilling, and tapping.

- Rapid Prototyping: Fast turnaround times to accelerate your product development cycle.

Materials We Process We work with a wide spectrum of materials to suit diverse industrial applications:

- Aluminum Alloys: 6061, 7075, 2024, 5052 (Aerospace, Automotive, Electronics).

- Stainless Steel: 303, 304, 316, 17-4 PH (Medical, Food Grade, Marine).

- Steel Alloys: 4140, 1018, 1045 (High-strength industrial components).

- Copper & Brass: C360, C110 (Electrical connectors, decorative hardware).

- Titanium: Grade 2, Grade 5 (Medical implants, high-performance racing).

- Engineering Plastics: POM (Delrin), Nylon, ABS, PEEK, PC, PTFE.

Quality Assurance & Precision Standards Quality is the cornerstone of Xiamen Dibo. We implement a rigorous quality control system to ensure every part is perfect:

- Tight Tolerances: Achieving up to ±0.005mm (depending on part requirements).

- Advanced Inspection: Equipped with CMM (Coordinate Measuring Machine), Optical Projectors, Digital Micrometers, and Hardness Testers.

- Full Traceability: Material Certifications and Dimensional Inspection Reports (FAI) provided with every shipment.

Surface Finishing Solutions We provide professional surface treatments to enhance durability and aesthetics:

- Anodizing (Type II & Type III Hard Coat, various colors)

- Powder Coating, Painting, and Chemical Film

- Bead Blasting, Polishing, and Mirror Finishing

- Electroplating (Zinc, Nickel, Chrome, Gold)

- Laser Engraving and Custom Marking

The Xiamen Dibo Advantage

- Competitive Factory Pricing: Direct manufacturing to reduce your procurement costs.

- Fast & Reliable Delivery: Optimized production scheduling to meet your critical deadlines.

- Expert DFM Support: Our engineers provide free Design for Manufacturing feedback to optimize costs and performance.

- Flexible MOQ: We support your growth from 1-piece prototypes to 100,000+ piece mass production.

Contact Us for a Fast Quote! Ready to start your project with Xiamen Dibo Metal Technology? Send us your 3D/2D drawings (STEP, IGES, DXF, PDF) today. Our team will provide a comprehensive quote within 24 hours.

Xiamen Dibo Metal Technology Co., Ltd. Your Trusted Partner in Precision CNC Machining.